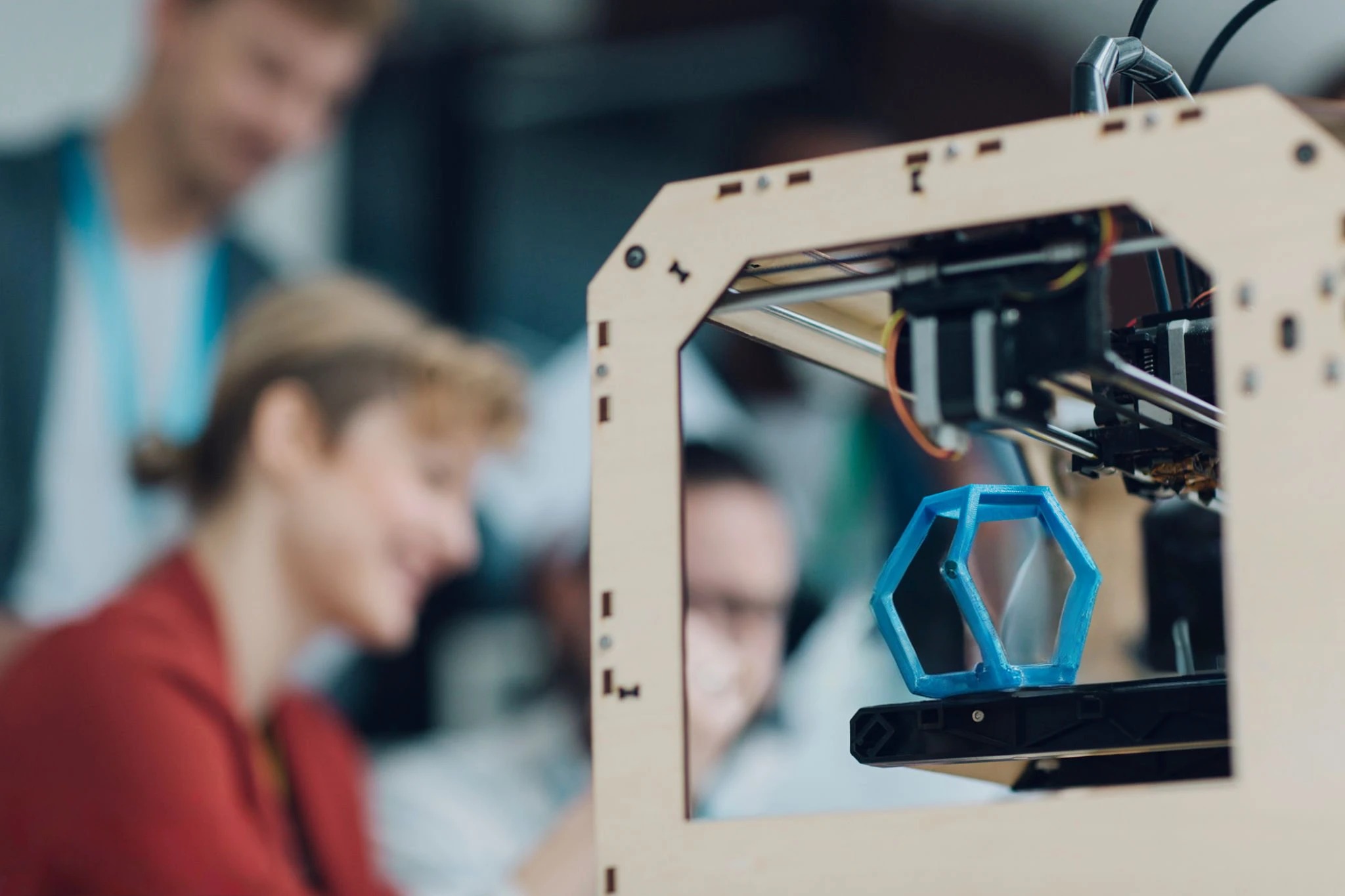

In 2025, 3D printing is poised to redefine entire industries, especially manufacturing and healthcare. As the technology matures, it will become a game-changer in producing everything from highly personalized healthcare solutions to custom-made components in manufacturing. What was once considered a novelty is now becoming an integral part of global economies, offering both enormous opportunities and a host of challenges. Let’s take a closer look at how this will revolutionize these two critical sectors in the near future.

1. Transforming Healthcare: From Prosthetics to Organ Printing

One of the most exciting advancements in 3D printing is its potential to revolutionize healthcare. The ability to create highly customized medical devices and even human tissues will drastically improve patient outcomes, reduce costs, and potentially save lives.

Custom Prosthetics and Implants

By 2025, the ability to 3D print prosthetics and implants tailored to an individual’s specific anatomy will be commonplace. Traditional prosthetics often require multiple fittings and can be uncomfortable for the wearer. In contrast, 3D-printed prosthetics are more customizable, allowing for precise, ergonomic designs that improve comfort and functionality. This technology is also opening up the possibility for people with limb differences. It allowes them to access affordable, high-quality prosthetics that were once out of reach.

Bioprinting: Printing Organs and Tissues

One ground-breaking healthcare development is bioprinting, using 3D printing to create living tissues and future organs. Though early in development, researchers aim for major progress by 2025 in tissue creation. Applications include skin grafts for burns and cartilage replacements for joint repair. The ultimate goal is to one day print fully functional organs, potentially solving the global organ transplant crisis. However, challenges remain, including ensuring tissue viability and vascularization for organ functionality.

2. Revolutionizing Manufacturing: On-Demand and Custom Production

Manufacturers across the world are harnessing the power of 3D printing to create products more efficiently and at lower costs. By 2025, this technology will be central to transforming production processes, leading to faster product development, more flexible designs, and significant cost savings.

On-Demand Manufacturing and Supply Chain Innovation

One of the biggest advantages of 3D printing is its ability to create products on-demand. Traditional manufacturing often requires large inventories and lengthy production cycles. 3D printing lets manufacturers produce parts on demand, cutting waste, inventory costs, and the environmental impact of mass production.

This on-demand approach benefits industries like automotive, aerospace, and consumer electronics, where personalized or low-volume products are in high demand. By 2025, many industries will adopt additive manufacturing as a core part of their supply chains. This adoption will streamline production and reduce delays caused by traditional logistics methods.

Customization and Personalization

Another key development in 3D printing will be the ability to offer highly customized products tailored to the specific needs and desires of consumers. In sectors like fashion, footwear, and automotive, 3D printing will allow for a level of personalization that was previously impossible. Consumers will be able to design their own products, from custom shoes to personalized car parts. They have them printed on-demand. This trend towards customization will reshape consumer expectations and push companies to focus on delivering products that cater to individual preferences.

Sustainability in Manufacturing

With increasing concerns about the environmental impact of mass production, 3D printing will be a crucial tool for making manufacturing more sustainable. The technology uses less material than traditional methods, leading to less waste and a lower carbon footprint. Additionally, as the materials used for 3D printing evolve, we can expect to see greater use of eco-friendly options such as biodegradable plastics and recycled materials.

In 2025, we may see companies using 3D printing to create products from sustainable materials, leading to a more circular economy. For example, products could be designed for easy recycling and repurposing, helping to minimize the environmental impact of manufacturing.

3. The Impact of 3D Printing on Industries Beyond Manufacturing and Healthcare

While manufacturing and healthcare are at the forefront, other industries will also benefit from the rapid advancements in 3D printing.

Architecture and Construction

In construction, 3D printing is set to change how buildings are designed and built. By 2025, 3D printing will be used to print not only individual building components but also entire structures. This technology will allow architects to design more complex, sustainable, and energy-efficient buildings. Additionally, 3D-printed homes could help address housing shortages, providing affordable, quick-to-build housing solutions in disaster-stricken or underdeveloped areas.

Food Printing

The food industry is also tapping into 3D printing to create customized meals. By 2025, 3D-printed food may become more common, with personalized nutrition options based on an individual’s dietary needs and preferences. While the technology is still in its infancy, it holds the potential to change how food is produced and consumed, especially in space exploration or remote environments.

Education and Research

3D printing will continue to expand in the educational sector. This is because it will enable students and researchers to bring their ideas to life. Universities and institutions will use 3D printers to create prototypes for scientific experiments, assist in designing teaching tools, and develop educational resources that were once costly or impractical to produce.

Challenges and Considerations

While the potential of 3D printing is enormous, challenges remain, including:

- Material Limitations: Although the range of materials for 3D printing is expanding, it is still limited compared to traditional manufacturing processes.

- Regulation and Standards: As industries like healthcare and aerospace adopt 3D printing, regulatory challenges will arise, especially in ensuring the safety and quality of printed parts.

- Cost of Equipment: Although 3D printing is becoming more accessible, the initial investment in high-quality printers can still be prohibitively expensive for smaller businesses.

Final Thoughts: A Game-Changer for the Future

In 2025, 3D printing will shift from a futuristic idea to a core technology across manufacturing, healthcare, and other fields. It enables on-demand, customized production, helping businesses boost efficiency, sustainability, and adapt quickly to consumer needs. This technology reduces waste and streamlines supply chains, creating more agile operations.

Healthcare will see major benefits from 3D printing, improving patient care through personalized treatments and breakthroughs in bioprinting. Advances will allow the creation of custom tissues and potentially organs, saving lives and transforming medical procedures. These innovations will make healthcare more precise and patient-focused than ever before.

Looking forward, 3D printing’s full impact will reshape industries, economies, and daily life worldwide. To maximize its benefits and overcome challenges, collaboration is essential among industries, governments, and innovators. Together, they can unlock 3D printing’s transformative potential for society’s long-term good.